A. Isifinyezo sokucaciswa

Ukucaciswa kwesixhumi esilingana ngokucindezela esikuthuthukisile sithi

kufinyezwe kuThebula II.

Kuthebula II, "Usayizi" usho ububanzi bokuxhumana besilisa (okuthiwa "Usayizi Wethebhu") ngo-mm.

B. Ukunqunywa Okufanelekile Kwebanga Lokuxhumana

Njengesinyathelo sokuqala sokwakhiwa kwetheminali yokulinganisa umshini, kufanele

thola uhla olufanele lwamandla okuxhumana.

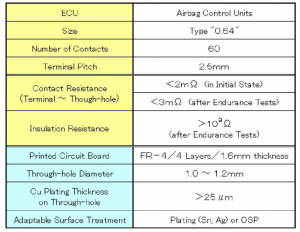

Ngale njongo, imidwebo yesici se-deformation ye

amatheminali kanye nezimbobo ezidlulayo zidwetshwa ngokohlelo, njengoba kukhonjisiwe

ku-Fig. 2. Kuboniswa ukuthi amandla okuxhumana aku-eksisi eqondile,

ngenkathi osayizi betheminali kanye namadayamitha we-hole ku-

i-eksisi evundlile ngokulandelana.

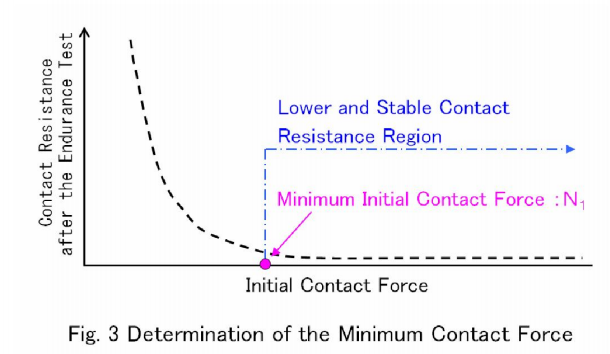

C. Ukunqunywa Kwamandla Okuxhumana Okuncane

Amandla amancane okuxhumana anqunywe ngu-(1)

ukuhlela ukumelana nokuxhumana okutholwe ngemva kokubekezela

izivivinyo ku-eksisi eqondile kanye namandla okuxhumana okuqala avundlile

eksisi, njengoba kukhonjisiwe kuFig. 3 ngokohlelo, kanye (2) nokuthola

amandla amancane okuxhumana njengokuqinisekisa ukumelana nokuxhumana

ephansi futhi ezinzile.

Kunzima ukukala amandla okuxhumana ngqo ngokusebenza kokuxhumana kwe-press fit, ngakho sikuthole kanje:

(1) Ukufaka amatheminali ezimbotsheni ezidabulayo, ezinawo

ububanzi obuhlukahlukene ngaphezu kobubanzi obunqunyiwe.

(2) Ukulinganisa ububanzi betheminali ngemva kokufakwa kusukela ku-

cross section cut isampula (isibonelo, bheka Fig. 10).

(3) Ukuguqula ububanzi betheminali obukalwe ngo-(2) bube yi-

amandla okuxhumana esebenzisa isici sokuguquguquka

umdwebo wetheminali etholwe empeleni njengoba kuboniswe ku

Umdwebo 2.

Imigqa emibili yetheminali deformation isho ukuthi

ubukhulu kanye nobuncane bosayizi betheminali ngenxa yokuhlakazeka phakathi

inqubo yokukhiqiza ngokulandelana.

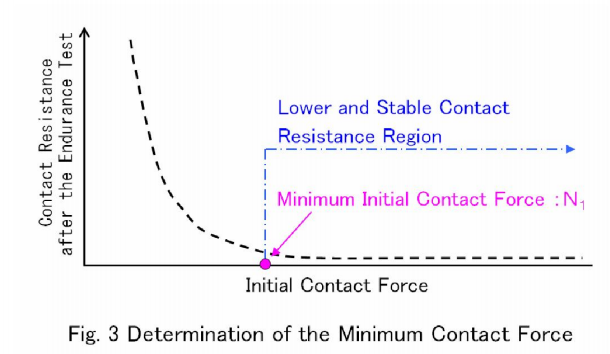

Ithebula II Ukucaciswa Kwesixhumi esisikhiqizile

Kuyacaca ukuthi amandla okuxhumana akhiqizwe phakathi

amatheminali kanye nezimbobo nakuba zinikezwa ngokuphambana kwezindlela ezimbili

imidwebo yamatheminali kanye nezimbobo ku-Fig. 2, okuyinto

kusho isimo esilinganiselwe sokuminyaniswa kwetheminali nangokunwetshwa kwembobo.

Sinqume (1) amandla amancane okuxhumana

okudingekayo ukwenza ukumelana nokuxhumana phakathi kwamatheminali kanye

nakuba-izimbobo ziphansi futhi zizinzile ngaphambi / ngemva kokubekezela

izivivinyo zokuhlanganiswa kosayizi obuncane betheminali kanye

ubukhulu be-diameter yembobo, kanye (2) namandla amakhulu

okwanele ukuze kuqinisekiswe ukumelana nokwahlukanisa phakathi kwendawo eseduze

izimbobo zidlula inani elishiwo (109Q yalokhu

development) kulandela izivivinyo zokukhuthazela ze

inhlanganisela yobukhulu bobukhulu betheminali nobuncane

ngokusebenzisa imbobo ububanzi, lapho ukonakala insulation

ukumelana kubangelwa ukumuncwa komswakama ku

indawo eyonakele (encishiwe) ku-PCB.

Ezigabeni ezilandelayo, izindlela ezisetshenziselwa ukunquma

ubuncane kanye namandla okuxhumana aphezulu ngokulandelana.

D. Ubuningi Bokunqunywa Kwamandla Okuxhumana

Kungenzeka ukuthi i-interlaminar delaminations ku-PCB ifake

ukwehla kokumelana ne-insulation ezingeni lokushisa eliphezulu kanye nokungena

umoya omswakama lapho ungaphansi kwamandla okuxhumana amaningi,

okukhiqizwa ukuhlanganiswa kobuningi

usayizi wetheminali kanye nobubanzi obuncane bembobo.

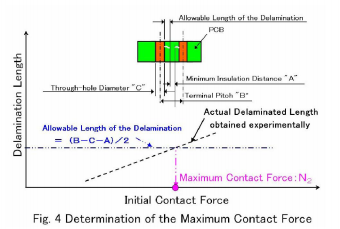

Kulokhu kuthuthukiswa, amandla okuxhumana aphezulu avumelekile

itholwe kanje;(1) inani lokuhlola le-

ubuncane bebanga elivumelekile lokwahlukanisa elithi "A" ku-PCB lali

etholwe ngokuhlolwa kusengaphambili, (2) okuvumelekile

ubude be-delamination bubalwe ngokwejometri njenge-(BC A)/2, lapho u-"B" kanye no-"C" kungumsindo wokugcina kanye

ububanzi bembobo ngokulandelana, (3) i-delamination yangempela

ubude ku-PCB ngamadayamitha ahlukahlukene embobo iye yaba

etholwe ngokuhlolwa futhi yahlelwa ngobude obuncishisiwe

uma kuqhathaniswa nomdwebo wokuqala wamandla othintana naye, njengoba kuboniswe kumfanekiso wesi-4

ngohlelo.

Ekugcineni, amandla okuxhumana aphezulu anqunywe kanjalo

ukuze angeqi ubude obuvumelekile bokuhlukanisa.

Indlela yokulinganisa yamandla okuxhumana iyafana ne

kushiwo esigabeni esandulele.

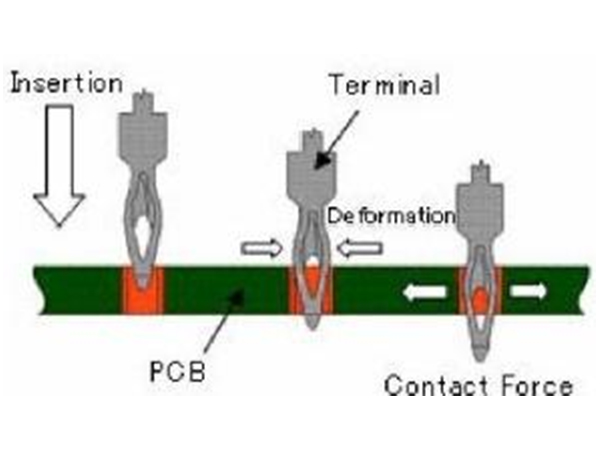

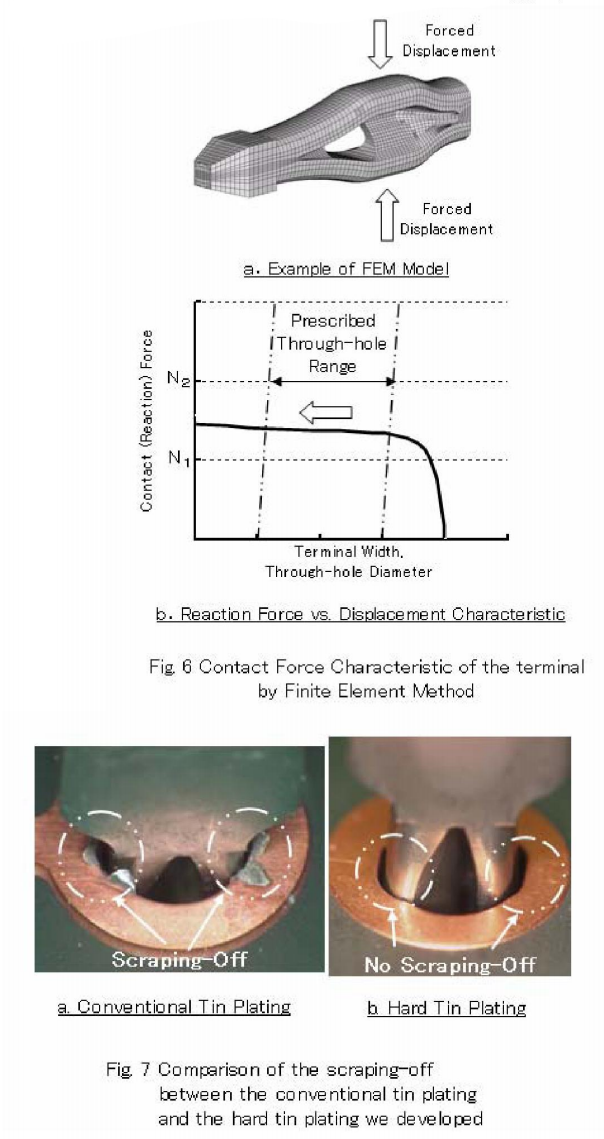

E. I-Terminal Shape Design

Umumo wetheminali uklanywe ngendlela yokuthi ukhiqize

amandla okuxhumana afanelekile (N1 kuya ku-N2) emgodini onqunyiwe

ububanzi be-diameter ngokusebenzisa i-elementi enomkhawulo wobukhulu obuthathu

izindlela (FEM), kufaka phakathi umphumela we-deformation yangaphambi kwepulasitiki

ukukhuthaza ekukhiqizeni.

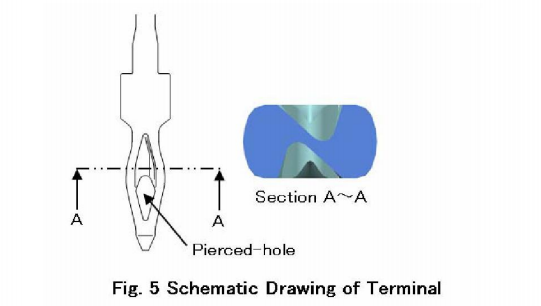

Ngenxa yalokho, siye samukela i-terminal, emise okwe-an

"Isigaba esiphambanayo somumo ongu-N" phakathi kwamaphoyinti okuxhumana eduze ne-

phansi, osekukhiqize amandla okuxhumana acishe afane

ngaphakathi kobubanzi obunqunyiwe bobubanzi bembobo, nge a

imbobo ebhoboziwe eduze kwethiphu evumela umonakalo we-PCB ukuba ube

kuncishisiwe (Fig. 5).

Kuboniswe ku-Fig. 6 isibonelo se-three-dimensional

Imodeli ye-FEM namandla okusabela (okungukuthi, amandla okuxhumana) vs

umdwebo wokugudluka otholwe ngokuhlaziya.

F. Ukuthuthukiswa Kwe-Hard Tin Plating

Kunezinhlobo ezahlukene zokwelapha zangaphandle zokuvimbela

i-oxidization ye-Cu ku-PCB, njengoba kuchazwe ku-II - B.

Endabeni yokwelashwa kwe-metallic plating surface, njenge

ithini noma isiliva, ukuthembeka kokuxhumeka kukagesi kokucindezela-fit

ubuchwepheshe bungaqinisekiswa ngokuhlanganiswa ne

ezivamile Ni Plating terminals.Kodwa-ke, endabeni ye-OSP,ukufakwa kwamathini kumatheminali kufanele kusetshenziselwe ukuqinisekisa ukuthi isikhathi esideukuthembeka kokuxhumeka kukagesi.

Kodwa-ke, ukufakwa kwe-tin okujwayelekile kumatheminali (for

isibonelo, ukujiya okungu-1ltm) kukhiqiza ukukhuhlakwethiniphakathi nenqubo yokufaka itheminali.(Isithombe. "a" ku-Fig. 7)

futhi lokhu kukhishwa-off cishe kudala ama-short-circuits ngeamatheminali aseduze.

Ngakho-ke sesenze uhlobo olusha lukathayela oqinile

ukucwenga, okungaholeli ekutheni kukwalwe noma yiliphi ithiniokuqinisekisa ukwethembeka kokuxhumeka kukagesi kwesikhathi esidekanyekanye.

Le nqubo entsha yokucwenga iqukethe (1) ithini elincanyana elengeziwe

ukucwebezela endaweni engaphansi, (2) inqubo yokufudumeza (i-tin-reflow)

okwakha ungqimba oluqinile lwengxubevange yensimbi phakathi kwe

i-underplating kanye ne-tin Plating.

Ngoba izinsalela zokugcina ze-tin plating, okuyimbangela

yokukhuhla, kumatheminali iba mncane kakhulu futhi

isakaza ngokungafani kungqimba lwengxubevange, akukho ukukhuhlakweithini yaqinisekiswa ngesikhathi sokufakwa (Isithombe "b" kuUmfanekiso wesi-7).

Isikhathi sokuthumela: Dec-08-2022

I-YouTube

I-YouTube