A.nakuba i-Sumitomo Wiring Systems, Ltd. isivele ihlinzeka "i-First Generation Press-fit Connector" kumakhasimende ase-Europe kusukela ngo-2004, ibe nomkhawulo wokubekezelela ububanzi bembobo obungama-90ptm kuphela futhi lokhu kube yimbangela enkulu yobunzima ukwamukelwa kwamanye amakhasimende amaningi, kuhlanganise nasekhaya.

Ngakho-ke sesiqale ukuthuthukiswa "kwesixhumi se-Second Generation Press-fit Connector", esikwazi ukubhekana nezimo ezibanzi zokubekezelela ububanzi bembobo, silindele imakethe enkulu maduze nje.

B.Isicelo Sezixhumi Zezimoto Ukuze kusetshenziswe ubuchwepheshe bokuxhumanisa i-press-fit kuzixhumi zezimoto, bekufanele sicabangele izici ezithile, njengoba zibalwe ngezansi.

(1) Ukuthembeka Kokuxhuma Kwesikhathi Eside kuzimo zemvelo ezinzima kakhulu ezidingekayo kuzixhumi zezimoto.(Kuchayeke Ekudlidlizeni, Kwemishini Nokushisa Okushisayo njll.)

(2) Izindleko Eziphansi, okungenani ezilingana nalezo zenqubo yokugoqa okujwayelekile.

(3) Ukuzivumelanisa nezimo ezibanzi zokubekezelela ububanzi bembobo.

(4) Ukwethenjwa Kokuxhumana kwemithi ehlukahlukene ye-PCB.

Isitatimende (4) sisho ukuthi izindlela zokwelapha ezehlukene, ezifana ne-"Immersion Plating (tin noma isiliva)" kanye "Ne-Organic Solderability Preservative (OSP)" zisanda kuthuthukiswa futhi zamukelwa ukuvimbela ukufakwa kwe-oxidation yezindawo zethusi ku-PCB njengezinye izindlela ze-HASL evamile. (Hot Air Solder Leveling) [2].Kodwa-ke, lokhu kwelashwa kwangaphandle kungase kuthinte ukwethembeka koxhumano lwe-press-fit, ngoba ukwelapha okungaphezulu ku-PCB kuhlangana ngqo namatheminali.

II.DIZANINA IZIHLAHLANDLELA

A. Isifinyezo sokucaciswa

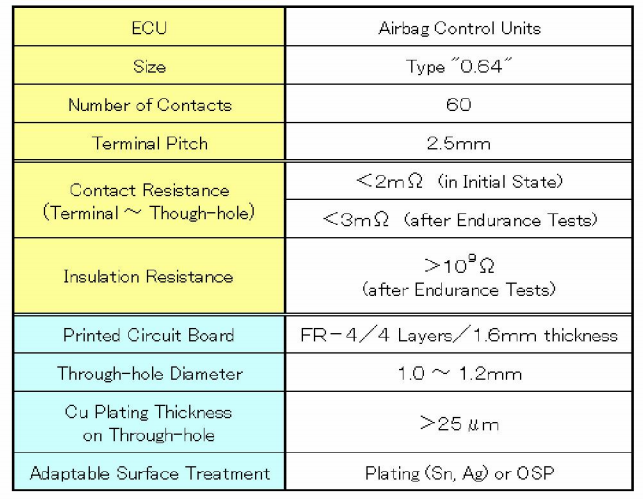

Ukucaciswa kwesixhumi esilingana ngokucindezela esikuthuthukisile sithikufinyezwe kuThebula II.

Kuthebula II, "Usayizi" usho ububanzi bokuxhumana besilisa (okuthiwa "Usayizi Wethebhu") ngo-mm.

B.Ukunqunywa Okufanelekile Kwebanga LokuxhumanaNjengesinyathelo sokuqala sokwakhiwa kwetheminali yokulinganisa umshini, kufanelethola uhla olufanele lwamandla okuxhumana.

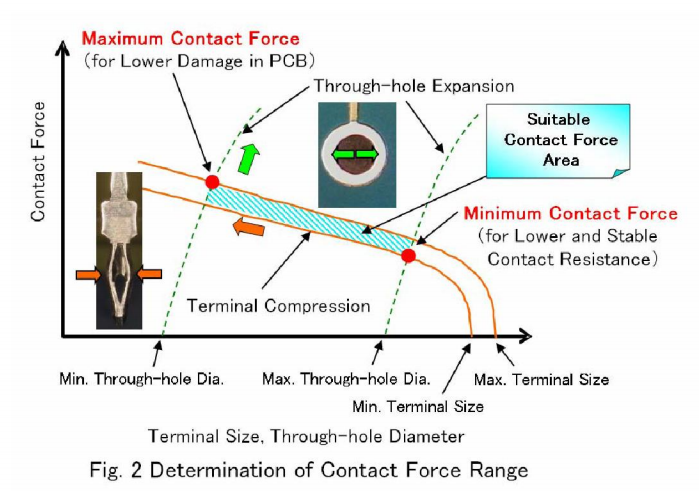

Ngale njongo, imidwebo yesici se-deformation yeamatheminali kanye nezimbobo ezidlulayo zidwetshwa ngokohlelo, njengoba kukhonjisiweku-Fig. 2. Kuboniswa ukuthi amandla okuxhumana aku-eksisi eqondile,ngenkathi osayizi betheminali kanye namadayamitha we-hole ku-i-eksisi evundlile ngokulandelana.

Imigqa emibili yokuguqulwa kwetheminali isho eyodwa yobukhulu obukhulu kanye nobuncane bosayizi wesitheminali ngenxa yokuhlakazeka ohlelweni lokukhiqiza ngokulandelana.

Ithebula II Ukucaciswa Kwesixhumi esisikhiqizile

Kuyacaca ukuthi amandla okuxhumana akhiqizwe phakathi kwamatheminali kanye nezimbobo ezitholakalayo anikezwa ukuphambana kwemidwebo emibili yamatheminali kanye nezimbobo kuFig. 2, okusho isimo esilinganiselwe sokuminyaniswa kwetheminali nangokunwetshwa kwembobo.

Sinqumile

(1) amandla okuthintana amancane adingekayo ukwenza ukumelana nokuxhumana phakathi kwamatheminali kanye nezimbobo zibe phansi futhi zizinze kakhudlwana ngaphambi/ngemuva kokuhlolwa kokuqina ukuze kuhlanganiswe amasayizi aphansi wetheminali kanye nobukhulu obukhulu obuyizimbobo, kanye (2) namandla amakhulu okwanele ukuqinisekisa ukuthi ukumelana nokufakwa phakathi kwezimbobo eziseduze kwedlula inani elishiwo (i-109Q yalokhu kuthuthukiswa) kulandela izivivinyo zokukhuthazela zenhlanganisela yobukhulu bokugcina obuphezulu kanye nobubanzi obuncane bembobo, lapho ukuwohloka kokumelana nokufakwa kubangelwa umswakama. ukumuncwa endaweni eyonakele (delaminated) ku-PCB.

Ezigabeni ezilandelayo, izindlela ezisetshenziswayo ukuze kutholwe amandla okuthintana amancane naphezulu ngokulandelana.

Isikhathi sokuthumela: Dec-07-2022

I-YouTube

I-YouTube