Ake sibone ukuthi isebenza kanjani:

Wisigqoko siCindezela-lingana?

I-Press-fit ukulingana kokuphazamiseka phakathi kwezingxenye ezimbili lapho ingxenye eyodwa iphoqelelwa ngaphansi kwengcindezi ingene emgodini omncane kwenye.

Ngokwezwi nezwi, kuwuhlobo lokungenela kokuphazamiseka.

Ubuchwepheshe be-press fit fit busetshenziswa kakhulu, futhi ukuxhumana ku-PCB kungolunye lwezinhlelo zakho zokusebenza ezijwayelekile.

Uma sichaza ngesiShayina, sivamise ukusebenzisa amatemu ahlukene afana ne-crimping, i-press fitting, kanye ne-crimping.Imboni ivamise ukusetshenziselwa ukusebenzisa ngokuqondile "Press fit" ukuchaza.Okugxilwe kakhulu kwalesi sihloko futhi uhlelo lokusebenza olulingana nabezindaba embonini ye-PCB (izikhonkwane eziningana ezijwayelekile zokucindezela).

Yiziphi izinzuzo ze-Press fit?

Izindlela eziyinhloko zokufaka izingxenye ku-PCB ukushisela bese ucindezela ukulingana.Ake siqhathanise izinzuzo kanye nokubi zalezi zindlela ezimbili zokuxhuma nedatha ethile evamile.

| Soldering | Cindezela-lingana | |

| ukusetshenziswa | 30-40 kW | 4-6 kW |

| imvelo | Umoya wokushisela nendawo yokuhlala | Ayikho indawo yokuhlala |

| izindleko | Udinga i-PA, i-PPS | Ayikho inkinga yokushisa okugodliwe, sebenzisa izinto ezingabizi kakhulu ezifana ne-PBT, PET njll. |

| Izisetshenziswa | Ukutshala imali okukhulu kanye nezindleko zendawo enkulu | Ukutshala imali okuphansi nendawo yosayizi omncane |

| Indawo etholakalayo | 5-15 mm | 2mm |

| Izinga lokukhubazeka | 0.05 kufanelekile | 0.005 kufanelekile |

Kusuka kudatha yokuqhathanisa, singabona ukuthi i-Press fit iyindlela engcono yokuxhuma i-PCB kune-welding ngokwezinkomba ezithile zokusebenza.Yiqiniso, ukushisela akusizi ngalutho, ngaphandle kwalokho ngeke kube namaphoyinti amaningi wokushisela ku-PCB.Isibonelo, ukushisela ngokuvamile kunokubekezelela okukhulu ukubekezelelana kwe-dimensional kwamaphini, futhi uxhumano lwe-welding luzinzile, Nokho, i-Press Fit ingcono ezinkomba eziningi zesici.

Izindlela zokuklama ze-Common Press fit

Ngaphambi kokwethula indlela yokuklama, kuyadingeka ukwethula amagama amabili avame ukusetshenziswa:

I-PTH: Ifakwe ngeHole

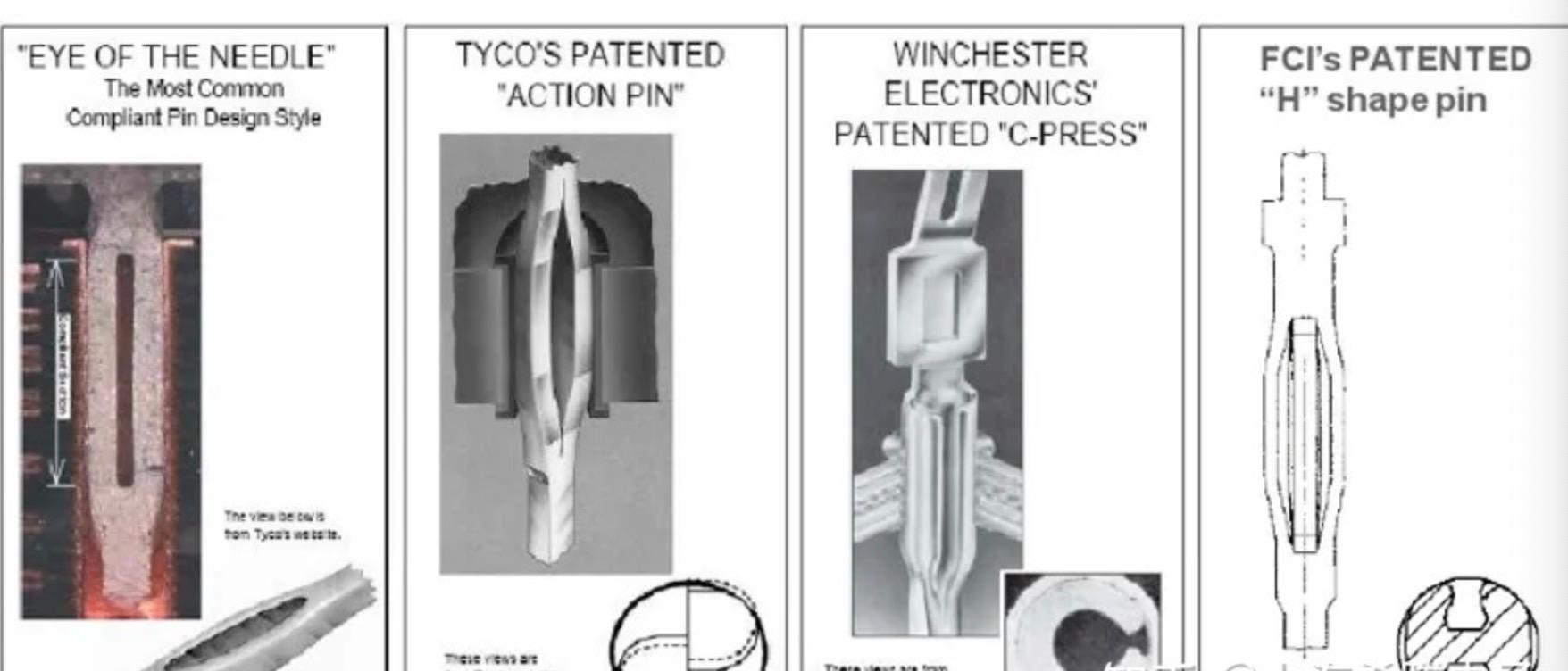

EON: Iso Lenaliti

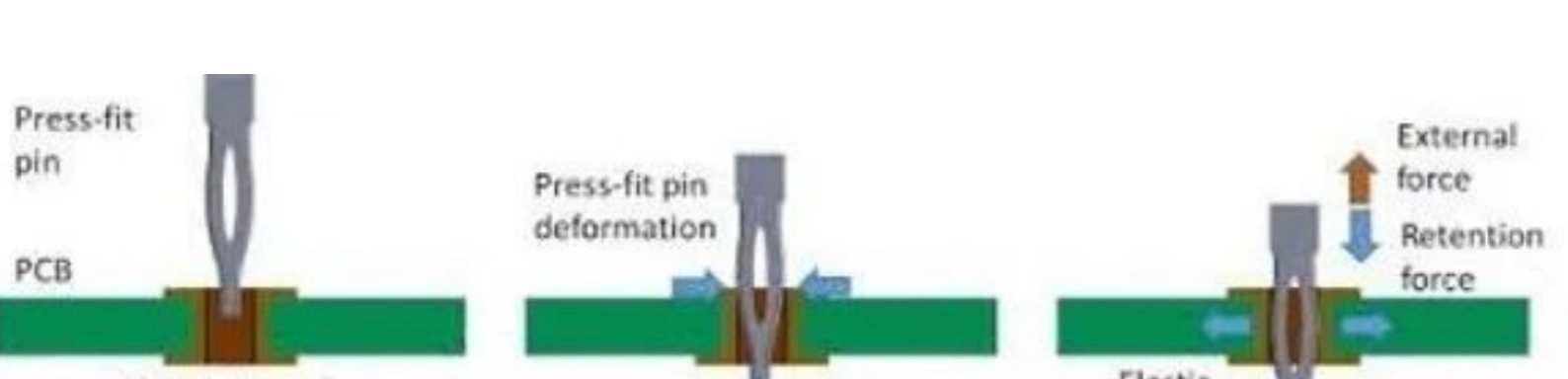

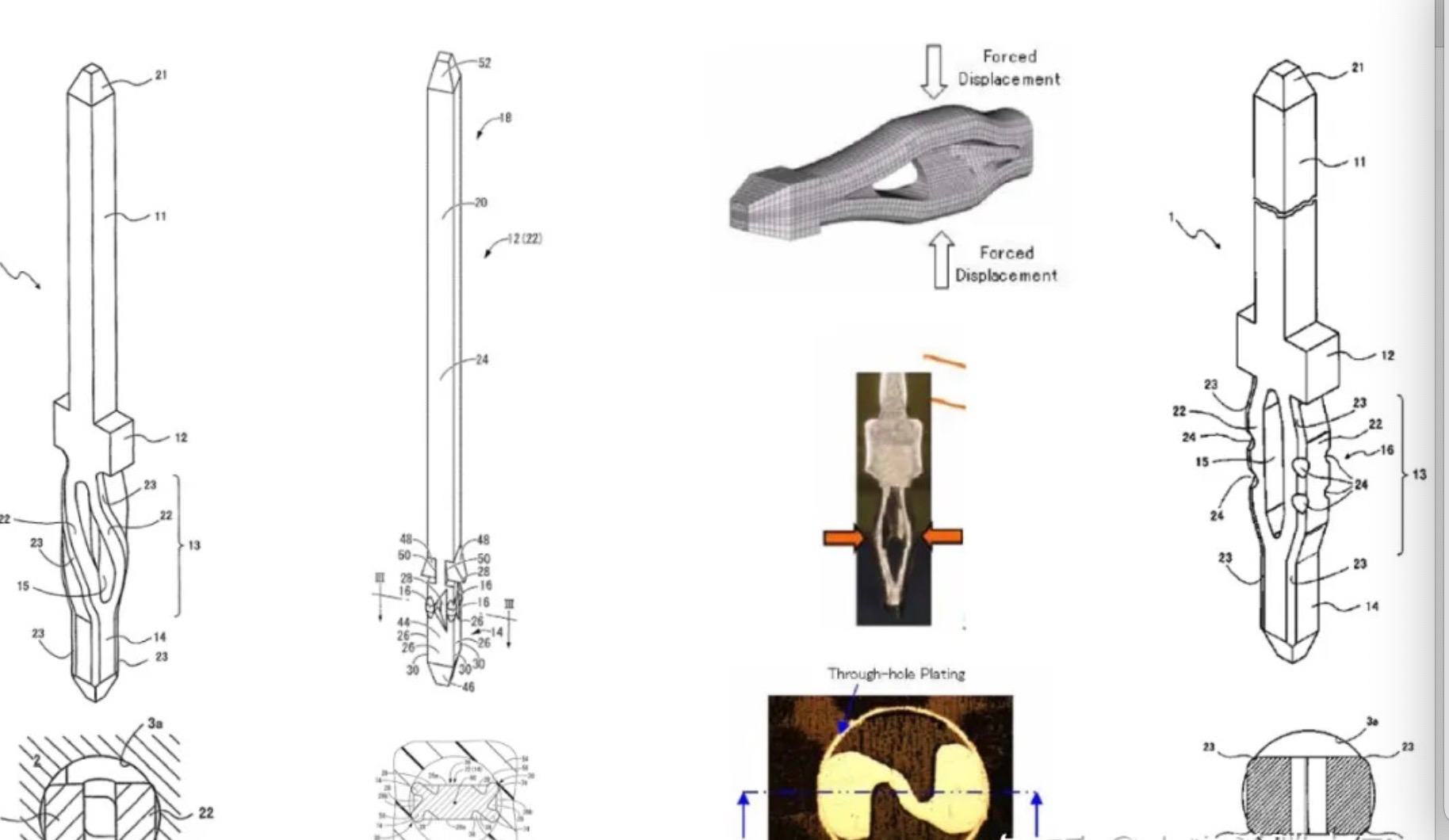

Okwamanje, izikhonkwane ezisetshenziswa ku-Press fit ngokuyisisekelo zingamaphini anwebekayo, aziwa nangokuthi amaphinikhodi athobelayo, ngokuvamile amakhulu ngobubanzi kune-PTH.Phakathi nenqubo yokuhlanganisa, izingxenye zenaliti zizokhubazeka, okuholela ekuxhumekeni kwendawo ene-PTH eqinile.Uma kuqhathaniswa nenaliti eqinile, inaliti ehambisanayo ingavumela ukubekezelelana okukhulu kwe-PTH.

Inalithi yembobo kaphini isiphenduke insakavukela emakethe.Ilula ekwakhiweni kwayo futhi ingasetshenziswa namalungelo obunikazi avulekile.Ngisho noma ingadingi umzamo omkhulu wokuklama, ingasetshenziswa futhi nezixazululo zokuklama ezenziwe ngomumo, ezinezici zamandla aphansi okufaka kanye namandla okugcina aphezulu.

Isibalo esingenhla sibonisa izinhlaka ezimbalwa ezijwayelekile zephini/itheminali.Esokuqala uhlelo oluvame kakhulu lokuklama.Uhlelo oluyisisekelo lokuklama i-pinhole lulula ngesakhiwo, kodwa ludinga ukulinganisa okuphezulu nendawo;Okwesibili umkhiqizo welungelo lobunikazi we-TE Company.Ngokusekelwe esakhiweni se-pinhole, ine-engeli yokuzungeza kancane, engakwazi ukuzivumelanisa nezimbobo ezahlukene.Kodwa-ke, inezidingo eziphakeme zobubanzi bembobo, futhi izokhiqiza amandla athile okujikeleza emgodini;Eyesithathu i-patent ye-Winchester Electronics yangaphambilini "C-PRESS", ebonakala ngesimo sika-C esivela esigabeni esiphambene.Izinzuzo ziwukuthi amandla okucindezela aqhubekayo, ukuguqulwa kwe-PTH kuncane, futhi okubi ukuthi i-PTH ene-aperture encane kunzima ukuyifinyelela;Eyokugcina iyiphinikhodi yokuxhumana yohlobo lwe-H ye-FCI Company.Inzuzo ukuthi kulula ukuyilawula lapho i-crimping, kodwa okubi ukuthi kunzima ukwenza iphinikhodi yokuxhumana.

Izinto ezijwayelekile kanye nenqubo yokukhiqiza

Izinto ezivamile ze-Pin zifaka ithusi le-tin (CuSn4, CuSn6), ithusi (CuZn), nethusi elimhlophe (CuNiSi), phakathi kwalo ithusi elimhlophe linokuqhuba okuphezulu, futhi izinga lokushisa lokusetshenziswa lingadlula i-150 ℃;I-coating ngokuvamile ihlanganiswe nge-electroplating noma i-hot dip plating μ m+1 μ M ye-Ni+Sn, i-SnAg noma i-SnPb, njll. Njengoba kuchazwe ngenhla, ukwakheka kwephinikhodi kuhlukahlukene, futhi umgomo oyinhloko ukukhiqiza iphinikhodi encane. amandla okucindezela kanye namandla amakhulu okubamba ngaphansi kwezimo zokukhiqiza okulula kanye nezindleko eziphansi.

Izinto ezisetshenziswa kakhulu ze-PTH yi-glass fibre+epoxy resin+copper foil, enogqinsi>1.6, futhi okunamathelayo kuvame ukuthayela noma i-OSP.Isakhiwo se-PTH silula.Ngokuvamile, inani lezendlalelo ze-PCB likhulu kuno-4. Indawo yokuvula ye-PTH ngokuvamile iqinile, futhi izidingo ezithile zincike ekwakhiweni kwephini.Ngokuvamile, ubukhulu be-copper plating cishe bungama-30-55 μ m.Ubukhulu bokufakwa kwethini ngokuvamile buyi>1 μ m.

Ukuhlaziywa kwenqubo yokufaka umshini/ukukhipha

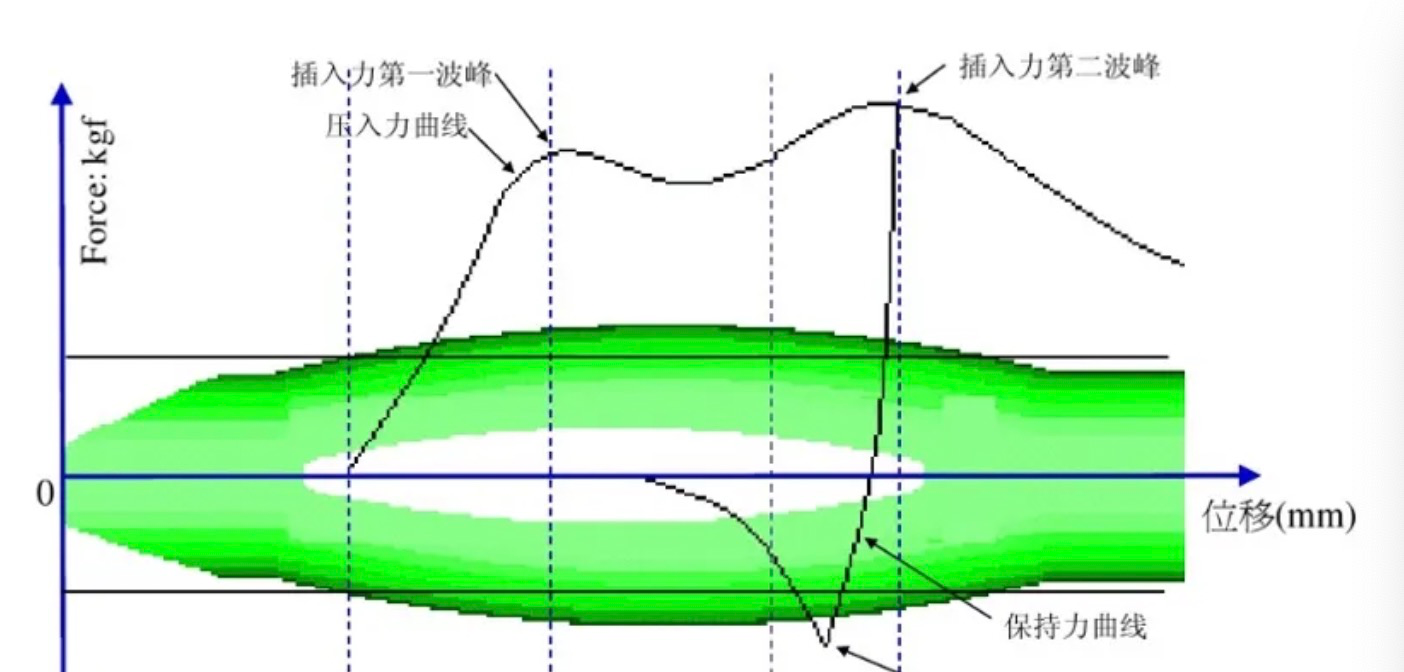

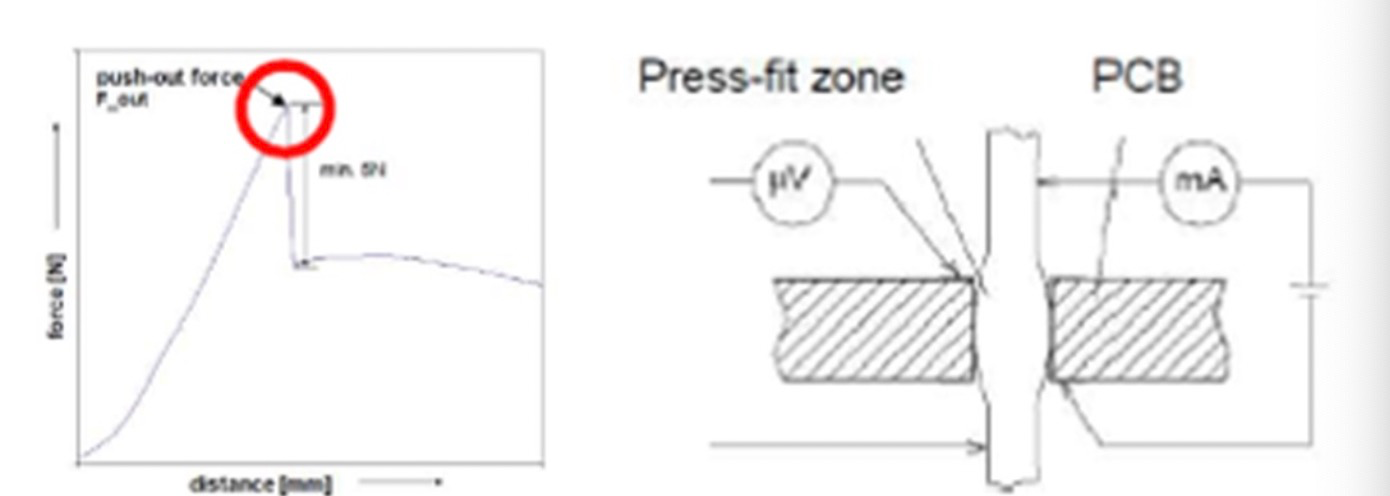

Ukuthatha isakhiwo sephinikhodi esivame kakhulu njengesibonelo, njengoba kukhonjisiwe emfanekisweni ongezansi, kunoshintsho olujwayelekile lwejika lengcindezi kuyo yonke inqubo yokucindezela nokukhipha, okubuye kuhlobane nesakhiwo sephinikhodi.

Cindezela kusaqhubeka:

1. Iphinikhodi ifakwa emgodini, futhi ithiphu ingena ngaphandle kokuguqulwa

2. Iphinikhodi iqala ukucindezela ukungena, i-EON iqala ukonakala, bese kuvela inani eliphakeme lamagagasi enqubweni yokucindezela.

3. Iphinikhodi iyaqhubeka nokucindezela, i-EON ngokuyisisekelo ayinakho ukuguquguquka okwengeziwe, futhi amandla okucindezela ayancipha kancane

4. Iphinikhodi iyaqhubeka nokucindezela phansi, ibangele ukuwohloka okwengeziwe, kanye nenani eliphakeme legagasi lesibili

Ivela kunqubo yokucindezela

Emasekhondini angu-100 ngemva kokuqedwa kokufakwa komshini, amandla okugcina azokwehla ngokushesha, ngokwehla okungaba ngu-20%.Kuzoba khona umehluko ohambisanayo ngokuya ngemiklamo ehlukene yamaphini;Amahora angama-24 ngemuva kokufakwa komshini wokunyathelisa, inqubo yokushisela ebandayo ye-Pin ne-PTH iqedwa ngokuyisisekelo.

Lokhu kubangelwa izici ezibonakalayo zensimbi, futhi kukhona indawo encane yokuthuthukiswa.Ingaqinisekiswa ukuthi amandla okugcina okugcina ayahlangabezana yini nezidingo zedizayini yomkhiqizo ngokuhlolwa kwe-push out force.

2. Amanye amamodi okuhluleka ngesikhathi sokufakwa kwephinikhodi

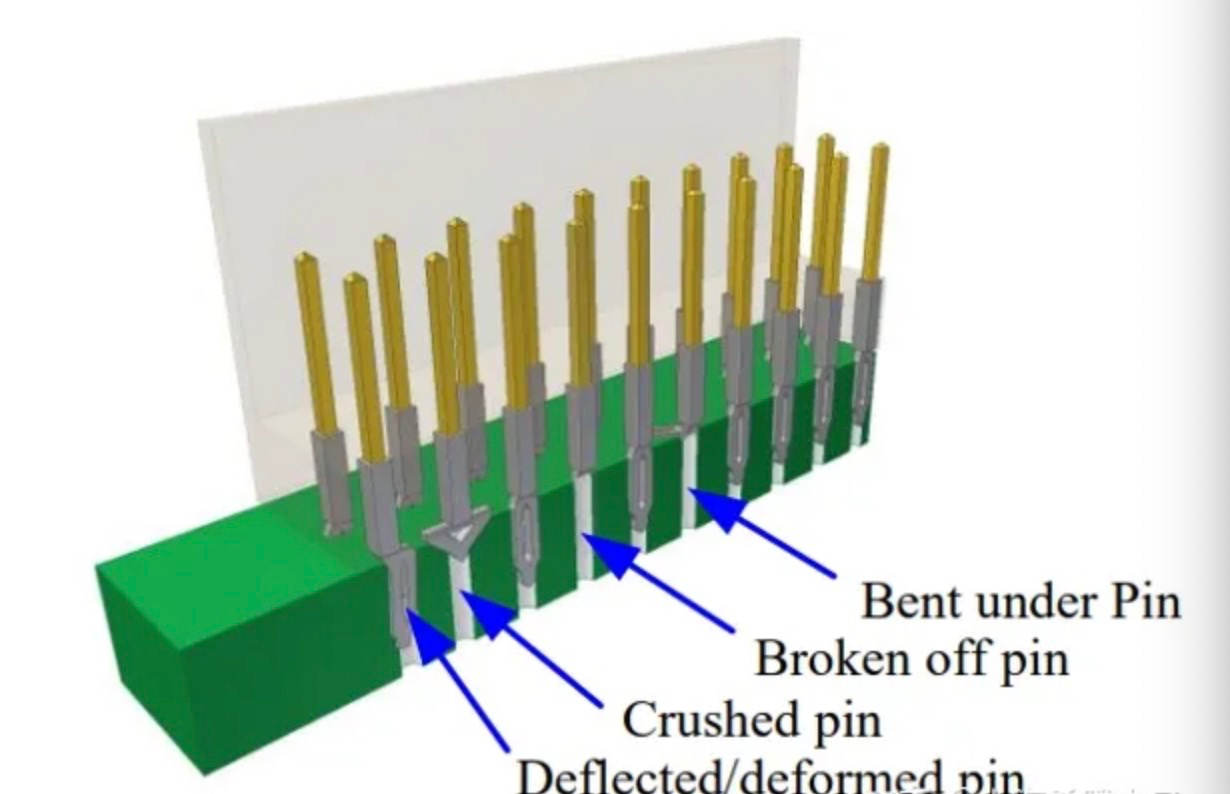

Njengoba kuboniswe emfanekisweni ongezansi, iphinikhodi ingase ikhubazeke, igaywe, igaywe, iphuke futhi igobe ngesikhathi sokufakwa.

Lezi yizindlela zokuhluleka okungenzeka zephinikhodi yokuxhumana phakathi nenqubo yokufaka umshini.Njengoba iphinikhodi yokuxhumana idinga ukufakwa ku-PTH, kungenzeka kakhulu ukuthi ayikwazi ukubonwa ngokubonakalayo ngemva kokucindezela, futhi umonakalo wamandla omshini ungase ungabonakali ngokuhlolwa kokusebenza kukagesi.

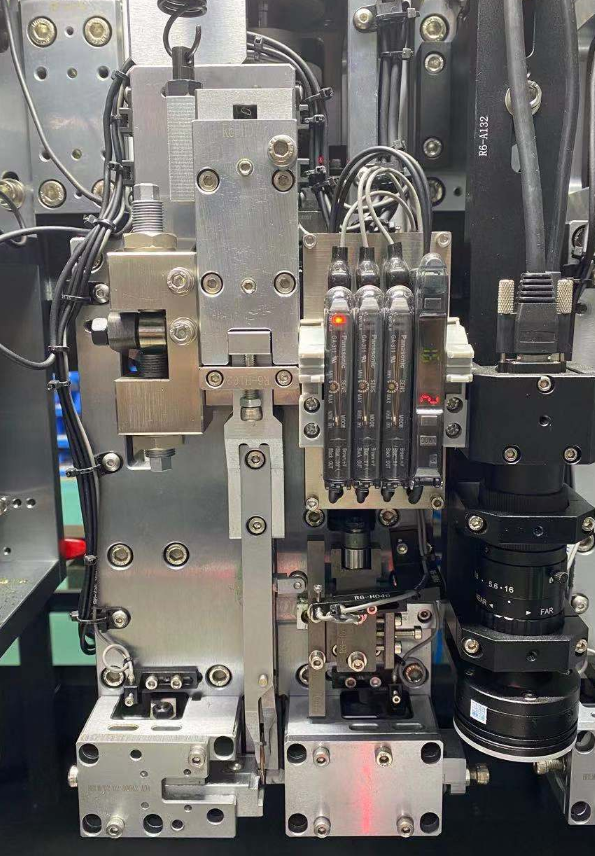

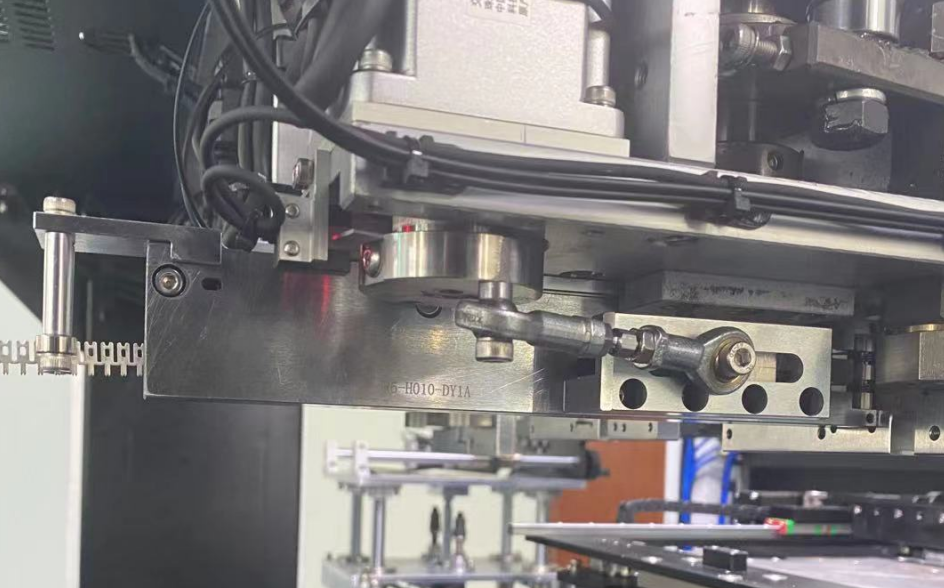

Lezi zindlela zokwehluleka zidinga ukugadwa phakathi nenqubo yokuhlanganisa abezindaba.I-PROMESS ihlinzeka ngephaseji elijikayo, iwindi, inani eliphezulu neliphansi kanye nezinye izindlela zokuqapha ukuze kuqinisekiswe ukuthi yonke inqubo yokufaka umshini wephini ngalinye iyalawuleka futhi inokwethenjelwa.Ungabona ikesi liboniswa kuvidiyo futhi.I-PROMESS inikeza ukunemba okuphezulu, izixazululo zokulawula inqubo engu-100% ukuze kuqinisekiswe ukuthi yonke imikhiqizo ephuma efektri ayinayo imikhiqizo enesici, Ukulawulwa kwenqubo nakho kunganciphisa udoti wezimboni webhodi le-PCB ngokwezinga elithile futhi kunciphise izindleko zokukhiqiza.

3. Isifunda Esifushane

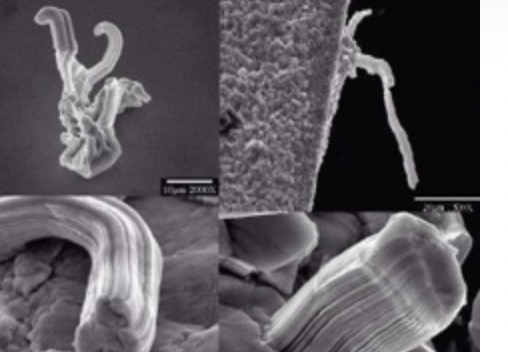

Ebusweni be-tin ehlanzekile, ukucindezeleka kuzokhuthaza ukukhula kwe-tin Whisker, okuzoholela kumjikelezo omfushane wesifunda ebhodini lesifunda eliphrintiwe, ngaleyo ndlela kubeka engozini umsebenzi wemodyuli.Imihlahlandlela yokuklama yokunciphisa ukukhula kwentshebe kathayela ihlanganisa ukunciphisa amandla okufaka kanye nokunciphisa ukujiya kwendawo yethini.

Izinto ezijwayelekile zokugqoka ze-PTH zifaka ithusi, isiliva, ithini, njll

Indlela yokuxazulula inkinga yamadevu ethini?

Ngesikhathi sokucindezela, amandla okucindezela akumele abe makhulu kakhulu, okuwukulawula inqubo yokucindezela.Ngemuva kokucindezela, ukuhlolwa kwesampula kungenziwa, futhi amadevu ethini azogcinwa amasonto ayi-12.

4. Vula isifunda

Umphumela we-Jet/donsela phansi:

Phakathi nenqubo yokucindezela ku-Pin, ibhodi lesekethe eliphrintiwe lingase lonakaliswe ngomshini.Uma ukungqubuzana kukhulu kakhulu, ingaphezulu lebhodi lesifunda lizoklwejwa, ukungqubuzana kuzokwanda, futhi ekugcineni i-PTH izokhishwa ngesigaba.Ukunciphisa ingcindezi kungagwema nomphumela we-jet.

Umphumela wokwenza ube mhlophe/delaminate:

Ngesikhathi sokunyuswa komshini, isakhiwo ngasinye sesendlalelo sebhodi lesifunda esiphrintiwe sizocindezelwa.Uma amandla asetshenzisiwe makhulu kakhulu noma i-PTH ingazinzile, ibhodi lesifunda eliphrintiwe lingase lincishiswe.Ngemva kwesikhathi esithile, umswakama uzongena emifantwini yebhodi lesifunda eliphrintiwe, okuholela ekunciphiseni ukusebenza kokuzihlukanisa

Lezi zinkinga ezimbili zingalawulwa ngokwezinga elithile phakathi nenqubo yokufaka umshini ngokulawula amandla okucindezela.Ngemuva kokuthi ukufakwa kwabezindaba sekuqediwe, umkhiqizo ungabuye uhlolwe ngokuhlolwa kokumelana nokuxhumana nokuhlaziywa kwe-metallographic.Ukuhlolwa kokumelana nokuxhumana kungasetshenziswa njengento yokuhlola evamile, futhi ukuhlaziywa kwe-metallographic ngokwako kuyawulimaza umkhiqizo, ngakho ukuhlolwa kwamasampula okuvamile kungenziwa.

Izindlela zokuhlola ukuthembeka komkhiqizo ezivamile

Enye yezindlela ezijwayelekile zokuhlonza ukuhlola ukuguga kanti enye ukuhlola izici zokuxhuma

Ukuguga kuwukulingisa isimo ngemuva kwesikhathi eside sisetshenziswa ngemishini yokuhlola.Izindlela ezijwayelekile zokuguga zihlanganisa:

1. Ukushisa okufudumele: - 40 ℃~60 ℃, ushintsho oluqhubekayo imizuzu engama-30

2. Izinga lokushisa eliphezulu: 125 ℃, amahora angu-250

3. Ukulandelana kwesimo sezulu: izinga lokushisa eliphakeme amahora angu-16 → amahora angu-24 kushisa futhi kunomswakama → amahora angu-2 izinga lokushisa eliphansi →

4. Ukudlidliza

5. Ukugqwala kwegesi: izinsuku eziyi-10, i-H2S, i-SO2

Ukuhlola ikakhulukazi ukuhlola amandla okuphusha nokusebenza kukagesi.

Izindlela ezijwayelekile zifaka:

1. Phusha ngaphandle amandla (amandla okubamba): > 20N (ngokuya ngezidingo zedizayini yomkhiqizo)

2. Ukumelana nokuxhumana: < 0.5 Ω (ngokwezidingo zokwakheka komkhiqizo)

Isikhathi sokuthumela: Nov-10-2022

I-YouTube

I-YouTube